Search:

D-Sub Connectors

Cable Mount

Series |

Description |

Crimp |

Solder Cup |

IDC |

High Density |

|---|---|---|---|---|---|

170 Series

|

Standard Density Crimp & Poke D-Sub Connectors |  |

|||

170 Series

|

170 Series Contacts (for Crimp D-Sub Connectors) |  |

|||

171 Series Solder Cup

|

Standard Solder Cup D-Sub Connectors | Stamped Contacts |  |

|||

172 Series Solder Cup

|

Standard Solder Cup D-Sub | Machined Contacts |  |

|||

172-E Series

|

Standard Solder Cup D-Sub | Machined Contacts | Economy |  |

|||

180 Series Contacts

|

180 Series Contacts (for Crimp D-Sub Connectors) |  |

|

||

180 Series Crimp & Poke

|

High Density Crimp & Poke D-Sub Connectors |  |

|

||

180 Series Solder Cup

|

High Density Solder Cup D-Sub Connectors | Stamped Contacts |  |

|

||

180-M Series Solder Cup

|

Solder Cup High Density D-Sub Connectors | Machined Contacts |  |

|

||

184A Series

|

Low Profile IDC D-Sub Connector |  |

Board Mount

Series |

Description |

Dip Solder |

Wire Wrap |

High Profile |

Right Angle |

Surface Mount |

Press Fit |

High Density |

|---|---|---|---|---|---|---|---|---|

171 Series PCB Dip Solder

|

Standard Straight D-Sub Connectors | Stamped Contacts |  |

||||||

172 Series High Profile

|

Standard High Profile D-Sub | Machined Contacts |  |

||||||

172 Series PCB Dip Solder

|

Standard Straight D-Sub Connectors | Machined Contacts |  |

||||||

172 Series Wire Wrap

|

Standard Wire Wrap D-Sub Connectors | Machined Contacts |  |

||||||

172-E Series

|

Standard PCB Dip Solder D-Sub Connector Straight | Machined | Economy |  |

||||||

173-E Series

|

Standard D-Sub | Right Angle .283" Footprint | Machined | Economy |  |

||||||

174-E Series

|

Standard D-Sub | Right Angle .370" Footprint | Machined | Economy |  |

||||||

178 Series

|

Dual-Port D-Sub | .750" Centers |  |

|

|||||

179 Series

|

Dual-Port D-Sub | .900" Centers |  |

||||||

180 Series PCB Dip Solder

|

PCB Dip Solder High Density D-Sub Connectors | Stamped Contacts |  |

|

|||||

180-M Series PCB Dip Solder

|

PCB Dip Solder High Density D-Sub Connectors | Machined |  |

|

|||||

181 Series

|

High Density D-Sub | Right Angle .350" footprint | Stamped |  |

|

|||||

181-M Series

|

High Density D-Sub | Right Angle .350" Footprint | Machined |  |

|

|||||

182 Series

|

Standard D-Sub | Right Angle .318" footprint | Stamped | Economy |  |

||||||

183 Series

|

Right Angle D-Sub Connectors .590" footprint | Stamped | Economy |  |

||||||

189 Series

|

Dual-Port D-Sub | .625" Centers |  |

|

|||||

190/200 Series

|

Standard & HD D-Subs | SMT Right Angle & RA Zero Footprint Through Hole |  |

|

|

||||

191 Series Press Fit

|

Standard Density | Press Fit D-Sub Connectors |  |

||||||

191 Series Vertical Low Profile

|

Standard Density | Vertical Low Profile | D-Sub Connectors |  |

||||||

193 Series

|

High Density D-Sub | Right Angle 0.125" Footprint | Stamped |  |

|

|||||

195 Series

|

High Density D-Sub | Vertical Low Profile | Stamped Contacts |  |

|

|||||

197 Series

|

High Density D-Sub | Vertical Low Profile | Machined Contacts |  |

|

|||||

198 Series

|

High Density D-Sub | Vertical High Profile | Stamped Contacts |  |

|

|||||

999 Series VG / HD Combo

|

VGA over Dual PS/2 ports - Stamped Contacts |  |

D-Sub Connector Applications

D-sub, rectangular D-shaped, d-sub connectors deliver one of the most commonly used and reliable connectivity solutions for the transmission of data, namely the RS-232 standard. This connector is used in computer serial ports and other widely used computer peripheral parallel ports. Over time, the D-sub connector has evolved to meet the demands of far more rigorous and demanding end-use applications including industrial, military and transportation equipment as well as outdoor commercial electronics such as boating and remote weather stations that require an IP67 D-sub to ensure the reliable transfer of signal in stressful and harsh environments.

Choosing the right D-sub connector for the application you have in mind is essential. With factors like costs, operating conditions and critical assessments to account for, your choice of everything from connector cabling to housing material and pin durability couldn't be more crucial.

At NorComp, our significant in-house expertise and knowledge of I/O interconnect products can help you select the right solution for your project. Remember that while D-sub connectors have slightly decreased in market share for standard consumer electronics, their applications in rugged military and critical commecrcial applications have only grown.

By manufacturing highly customizable, cost-effective and reliable I/O connections between devices and various electronic systems, ever more sophisticated systems - including those that are automated - can be connected quickly and securely so they operate without unnecessary interruptions or costly downtime. In addition, D-subs are easy to install and verify for quality assurance throughout their life cycle. Plus, they require little to no maintenance, which ultimately helps reduce overall operating costs regardless of the industry application.

D-Sub Connector Sizes and Variations

Whether you require D-subs for use in spaces that need robust EMI shielding or you're in the market for D-subs to form specific computer networks, such as token ring networks from days past or more advanced PCB & cabling environments, NorComp has the size, configuration and style of D-sub connector to deliver high performance within your electronic systems.

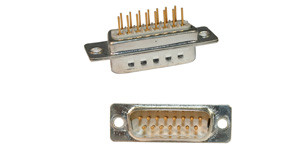

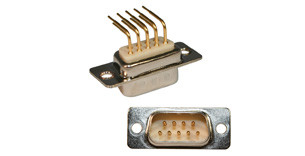

Standard Density D-Sub Connector

The standard density D-sub connector, also known as normal density D-sub connector, typically contains a pin layout of 9 pin, 15 pin, 25 pin, 37 pin & 50 pin positions housed in increasing shell sizes accordingly. They are available in both male (plug) and female (socket) variants with the male signal contacts/pins (current rating of 5A) spaced every 2.76mm in horizontal rows and the spacing of rows vertically at 2.84mm laid out half the distance between pins of existing rows.

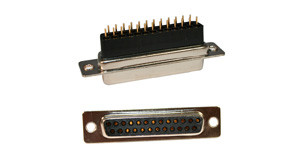

High Density D-Sub Connector

The high density D-sub connector is designed with 15 pin, 26 pin, 44 pin, 62 pin, & 78 pin variations in the same 5 increasing shell sizes as the standard density connectors previously described above. However, the male signal contacts/pins (current rating of 3A) are laid out only 2.3mm apart in horizontal rows & a closer 2.0mm vertical spacing between additional rows.

Other D-Sub Connector Configuration Options

The micro-D connector, also known as the micro-miniature d-sub connector, is approximately one-third to one-half the size of a standard d-subminiature connector specifically engineered for hand-held, compact & portable commercial applications that require a space-saving design solution with a secure & reliable signal transfer. These smaller d-sub connectors are considered high-density due to the close proximity of pin positions in 9 pin, 15 pin or 25 pin variations.

The “combo” d-sub, also referred to as a mixed contact connector, utilizes the same d-shaped shell to house either special high-current pins made larger to carry a higher amperage/voltage or coaxial contacts laid out beside signal contacts within the same connector shell footprint. These mixed layout connectors are designed in a broad range of mixed contact configurations and also made available in IP67 rated versions for more demanding industry application requirements.

- View the full NorComp product catalog for these and more I/O manufactured solutions.

- Follow this link for more information from Wikipedia on D-sub, D-subminiature connectors.

Related Categories

D-Sub Connectors

Categories

- Circular Connectors & Cable Assemblies

- D-Sub Connectors

- IP67 D-Sub Connectors

- D-Sub Backshells

- Micro-D Connectors & Cable Assemblies

- Power-D & Combo Mixed Connectors

- Push Pull Connectors

- D-Sub & Micro D Hardware

- Modular RJ45 Connectors

- USB Connectors

- D-Sub Adapters & Gender Changers

- SCSI .085"/.050"

- .050 Ribbon

- Headers & Receptacles

- Bayonet Connectors