Products

- Circular Connectors & Cable Assemblies

- D-Sub Connectors

- IP67 D-Sub Connectors

- D-Sub Backshells

- Micro-D Connectors & Cable Assemblies

- Power-D & Combo Mixed Connectors

- Push Pull Connectors

- D-Sub & Micro D Hardware

- Modular RJ45 Connectors

- USB Connectors

- D-Sub Adapters & Gender Changers

- SCSI .085"/.050"

- .050 Ribbon

- Headers & Receptacles

- Bayonet Connectors

New Technology In Factory Robotics

New Developments in Robotics for Factory––and Beyond

It makes sense that dangerous tasks for humans should be good candidates for robotic interventions. The same might be said for boring tasks.

The functions of a factory feature both these categories. For years, industrial facilities have been the first to experiment with robots in new applications.

In this post, we’ll take a look at the most promising developments in robotics today and how the same strategies are spilling over into areas of work well beyond the factory.

Material Handling

Raw materials entering factories and warehouses can bring with them potential injuries for workers. Sharp edges, rough surfaces, heavy loads, or chemical coatings are just a few of the hazards.

It makes perfect sense that these tasks should go to robots, and today’s mobile bots can do more and more material handling on the factory floor, moving quicker while holding heavier objects. They can transport materials between workstations, load and unload goods from trucks or conveyor belts, and gather shelved items for shipments (“case picking”).

For companies, the reduction of risk alone — think fewer back injury claims and out-of-commission workers — may make the investment in robotics worthwhile. And letting the robots do the heavy lifting also gets supplies moving faster, improving productivity and streamlining operations.

At a time when labor shortages are hampering manufacturing and logistics, mechanical material movers are gaining traction. Robots that can fetch pallet sized loads normally needing a forklift driver are now being adopted in many different industries. According to a recent survey, 31 percent of facilities said they were planning to roll out the technology in 2023.

|

Suggested Connectors for Drive Motors |

|

|

M-SERIES D-Sub |

|

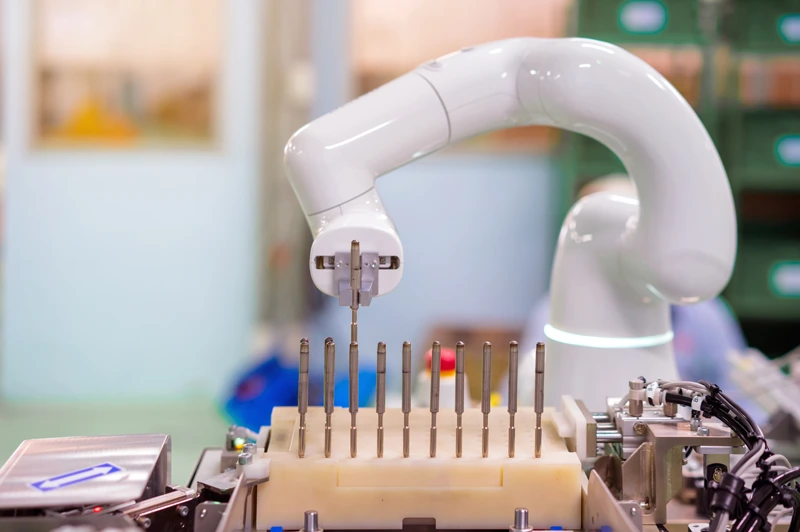

Assembly and Manufacturing

Robots excel in repetitive and precise tasks, making them perfect candidates for assembly line roles. These were the first tasks to employ factory robotics: welding, soldering, screwing, and painting with high accuracy and consistency.

Today, assembly in the hands of robots need not be one-dimensional. MIT Center for Bits and Atoms has been working on Voxels Assembler Robot, which self-assembles from modular pieces. In so doing it can also put together pretty much any 3D structure, even ones much larger than itself.

This R&D concept is attracting attention because of the potential on many manufacturing fronts. Instead of a large piece of tooling or a giant machine building a large product, it could instead be achieved by numerous small self-assembling miniature machines.

|

Miniaturized Robotic Connectors |

Quality Inspection

What is more boring for a human worker than repetitive assembly tasks? Repetitively inspecting assembly tasks afterward.

Before accurate image recognition, visual quality control responsibilities could only be performed by human eyes. This past decade has seen a giant leap in advanced vision systems for quality inspection in factories. They can instantaneously spot defects in products, measure dimensions, and verify adherence to specifications. In many cases in manufacturing, automated inspection now supersedes manual inspection in accuracy and efficiency.

What about outside the factory? Inspection and monitoring of the built environment is a necessary but costly task that is now finding robotic solutions. Surveying pipelines, monitoring the stress underneath bridges, or measuring miles of fencing or utility lines can be cumbersome for humans, but far easier for visual systems attached to unmanned aerial vehicles (UAV) — drones — or ground or marine mobile bots. Specialty robots can even be trained to climb up walls or along cables, inspecting as they go.

|

Camera and Sensor Connectors |

|

|

M-SERIES |

|

Collaborative Tasks

As if in answer to the call, “I could use an extra hand with this,” come collaborative robots, or cobots. These machines work alongside humans, sharing tasks and workspace as a sort of third arm. Typically they come equipped with sensors and safety features to avoid harming their companion.

Cobots are employed in various applications, such as assisting with heavy lifting, performing repetitive tasks, or handling delicate operations. Cobots help to reduce physical strain on workers and enhance workstation efficiency.

Specialized cobots are now spreading out from factory settings to find new jobs in kitchens as prep cooks. The E-SERIES from Doosan can be programmed to prepare almost any food or beverage. It can deep-fry tempura, steam a latte, or make piles of PB&Js. For chefs, the same strategy applies: delegate repetitive and potentially harmful (e.g. grease-splattering) tasks to machines.

|

Best Connectors for Waterproof Designs |

|

Hazardous Environments

Robots are particularly valuable in handling tasks in hazardous environments unsafe for the rest of us. Beyond the bomb-disposal robots used by police, there are many other dangerous situations that could use an invulnerable steel shell, such as working with toxic substances, extreme temperatures, or exposure to harmful radiation.

One recent development with this intention comes from DEEP Robotics, with a quadrupedal “rescue dog” called Jueying X20. While wheeled bots are ideal for smooth warehouse floors, quadrupeds excel on uneven ground. The robot can easily step through risky debris fields in post-disaster areas, over piles of rubble, or up and down the stairs of crumbling buildings.

|

Rugged connectors for hazardous conditions |

|

|

820K Series Circular Push-Pull Connectors |

|

Robotics Resources

Consult our industrial robotics brochure for an overview of all the premium electronic components NorComp offers.

To help make the right choice, see our resource guide on robotic connectors.

As the leading global supplier of connectors, NorComp can supply a solution for any robotic application ––even those with unique manufacturing specifications.

Ask a NorComp specialist about sourcing and customization options for robotic parts.

Go Back