Products

- Circular Connectors & Cable Assemblies

- D-Sub Connectors

- IP67 D-Sub Connectors

- D-Sub Backshells

- Micro-D Connectors & Cable Assemblies

- Power-D & Combo Mixed Connectors

- Push Pull Connectors

- D-Sub & Micro D Hardware

- Modular RJ45 Connectors

- USB Connectors

- D-Sub Adapters & Gender Changers

- SCSI .085"/.050"

- .050 Ribbon

- Headers & Receptacles

- Bayonet Connectors

Connecting the Industrial World: A Practical Guide to M12 Connector Codes

M12 circular connectors play a critical role in keeping industrial systems running reliably. With a compact 12 mm form factor and standardized coding system, M12 connectors enable safe, reliable, and consistent connections for signal, data, and power across a wide range of applications, from factory automation to robotics.

This article offers a practical breakdown of M12 connector coding and how it ensures safe mating, dual-sourcing flexibility, and compatibility across harsh environment use cases.

Why Coding Matters

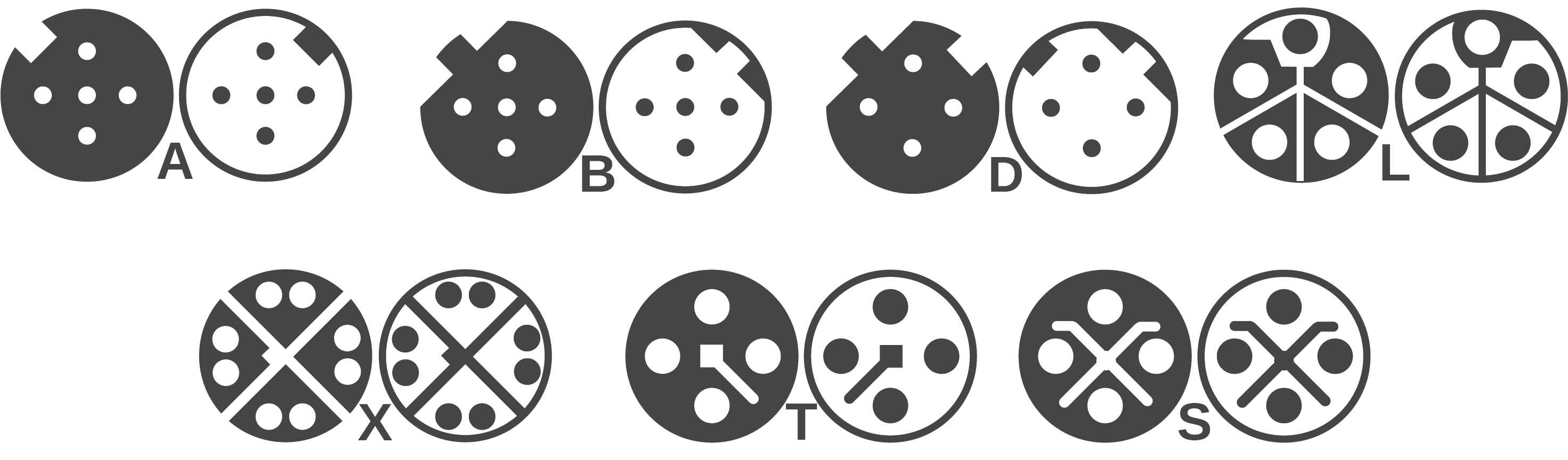

M12 connector coding does more than just organize connector types—it prevents mismating and wiring errors. Each code (A, B, D, X, etc.) defines both functionality (signal, data, or power) and includes physical keying that ensures only the correct plug and socket can mate. This prevents incorrect pairings that could damage equipment or compromise reliability.

While the number of pins often correlates with a specific code, it’s the physical keyway that guarantees safe and proper connection. For engineers, this means fewer headaches on the assembly line and fewer support tickets post-install.

Benefits for Design and Supply Chain Teams

-

Design Flexibility: Coding enables consistent electrical performance across similar devices and systems.

-

Field Safety: Eliminates incorrect mating or voltage mismatches.

-

Sourcing Confidence: Enables dual sourcing from multiple suppliers by ensuring connector compatibility by code.

Common M12 Codes and Their Use Cases

A-Coded M12 — The default M12 coding, used for general-purpose sensors, DC power, and signal connections. Found in industrial I/O modules, sensors, and LED field devices. Available in 3 to 12 pins.

B-Coded M12 — Used in industrial networks such as Profibus and Interbus. Supports signal/data communication between PLCs and field devices.

C-Coded M12 — Designed for AC power transmission with 2+PE or 3+PE pin layouts. Common in actuators and AC-powered motors.

D-Coded M12 — Optimized for 100 Mbit Ethernet communication. Popular in factory automation networks where reliability is key.

X-Coded M12 — Built for high-speed Ethernet (up to 10 Gbit/s). Features internal pair separation to reduce crosstalk. Used in high-res imaging, IIoT, and SCADA systems.

Emerging M12 Connector Codes

S-Coded M12 — AC power delivery for high-load equipment. Designed as a rugged upgrade to C-coded types.

T-Coded M12 — DC power up to 12A/63V. Used in motors, drives, and power-intensive industrial controls.

K-Coded M12 — 3-phase AC power delivery, often up to 630V and 12A. Ideal for compact, high-load equipment.

L-Coded M12 — DC power distribution for LED lighting and control boxes. Rated up to 16A/63V in compact form.

P-Coded M12 — Intended for hybrid signal/power use. While not widely adopted, they provide convenience in quick-change equipment.

NorComp: Built for the Industrial Environment

NorComp's VULCON™ M12 series includes a full suite of standard and emerging codes (A, B, C, D, K, L, S, T, X) across:

-

Circular Connectors: IP67/IP68 rated, available in 3–17 pins

-

Cable Assemblies: Molded, shielded, and ready for deployment

-

Stainless Steel Options: Ideal for corrosive or sterile environments

-

Adapters & Splitters: For efficient system layouts and flexibility

Built to perform in demanding environments, NorComp’s VULCON series helps ensure system uptime with rugged performance and proven reliability.

Want to discuss your M12 application or request a sample? Reach out to NorComp or connect with one of our distribution partners.

Go Back